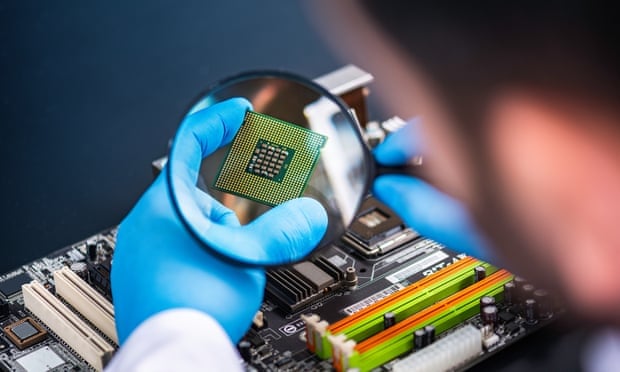

The deficiency of micro processors tormenting enterprises all throughout the planet and assisting with energizing expansion could last an additional two years, the manager of IBM has said.

With the worldwide vehicle industry assessed to lose $110bn this year because of the chip deficiency, IBM’s leader, Jim Whitehurst, told the BBC on Friday that the tech business was battling to stay aware of interest welcomed on by the returning of the world economy.

A few processing plants had to close when the pandemic originally struck in 2020. The build-up underway was compounded by taking off interest for chips from a blast in deals of PCs, game consoles and cell phones as individuals were constrained into lockdown.”There’s simply a major slack between from when an innovation is created and when [a manufacture plant] goes into development and when chips come out,” Whitehurst revealed to BBC world business news.

“So in all honesty, we are taking a gander two or three years … before we get sufficient gradual limit online to ease all parts of the chip lack.”

He said the business may need to consider changes to the manner in which micro processors were utilized.

“We must gander at reusing, broadening the existence of specific kinds of registering innovations, just as speeding up interest in these [fabricating plants], to have the option to as fast as conceivable get greater limit on the web,” he said.

Numerous carmakers dropped orders for contributes 2020 when they retired processing plants in the pandemic however have been gotten out as request has thundered back more rapidly than expected.

The counseling firm AlixPartners said on Friday that the emergency will hit the creation of 3.9m vehicles this year, pushing the expense for the business to $110bn from a previous conjecture of $61bn.

Automakers are presently taking a gander at growing direct associations with semiconductor creators, said Imprint Wakefield, co-head of AlixPartners’ worldwide auto practice.

“These things are stunned into reality,” he said.

Passage has divided creation of vehicles through to June this year as a result of the emergency and said on Thursday that it was overhauling car segments to utilize more open chips.Jim Farley, talking at Portage’s online yearly investor meeting, said it was weighing different techniques for the future, including building a support supply of chips and marking manages plants that make the wafers utilized in semiconductors.

The chip deficiency has caused automakers worldwide to reduce creation. A month ago, Passage said the issue would cost it $2.5bn this year and split its vehicle creation in the subsequent quarter, when the deficiency would be best case scenario. The lack has constrained Passage now and again to sit creation of its exceptionally beneficial F-150 pickup trucks.

The deficiency of creation has pushed up costs. Around 33% of the stun 4.2% expansion in US swelling this week was down to higher vehicle and truck costs.

“Inflationary pressing factors are building a direct result of the returning of the economy, inventory network issues and a worldwide semiconductor lack,” said Ryan Sweet, a senior market analyst at Moody’s Examination in West Chester, Pennsylvania.

The deficiencies have additionally influenced ventures, for example, the production of home devices from clothes washers to toothbrushes that depend on both memory and handling chips.

Samsung, which drives the assembling of memory chips, has said creation of TVs and different apparatuses would be influenced by the deficiencies.

The assembling of better quality handling chips is overwhelmed by Taiwan with 92% of the world’s most exceptional semiconductors made by Taiwan Semoconductor, otherwise called TSMC.